Development of the Rim Lathe

The rim grew out of an intense desire to solve some of the fundamental problems of banjo production for the small shop. Normal wood lathes are unsuitable because they require that cutting tools be controlled by hand. Metal lathes would seem the obvious choice since they have accurate control of cutting tools because they are moved by mechanical means. Unfortunately metal lathes that have the capacity to turn a banjo rim are unsuitable because they are large, heavy and expensive.

The lathes described in this artical represent several years of loving research and development to deliver the most accuracy for the least cost possible. As much as possible the designs components include items that are readily available and access to which has been steady over a number of years.

|

In the Beginning... Before there was a rim lathe I created a router-based solution. Click here for the article. I made my first three rims with this arrangement and achieved a great deal of accuracy. The major failing of this solution that it is not capable of cutting the inner diameter of the rim efficiently. |

|

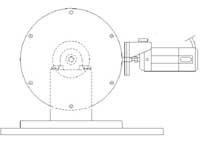

Prototype 1 |

|

Prototype 2 Prototype 2 major components include a lathe head with the brand name Pit Bull, which is similar in design to other imported lathes supplied by Grizzly and others. Prototype 2 was completed in 2005. The major advancements in Prototype 2 include the use of an expanding jaw chuck and moving away from a router for all major turning operations. I still use a router for decorative elements. |

|

Prototype 3 Prototype 3 was completed in September 2007. It exceeds my expectaions for accuracy and speeding up production. I was not able to make a machine robust enought to cut metal, but it is wonderful on even the densest of woods. The self-made lathe head can turn at very slow speeds which makes rough turning safe and effective.. |

|

Pennington Standard Lathe Modification Dan Pennington took some of my ideas and used them to modify a standard lathe. This is an effective way to go with much less work. more... |